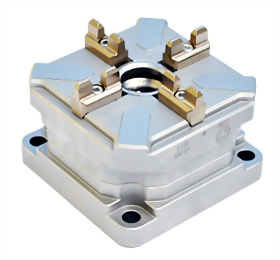

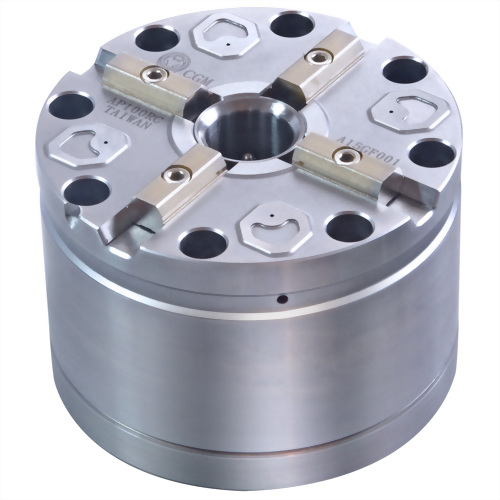

Model :

AD-148RC

AD-148RC is a special clamping tool derived from various conditions such as high temperature, high pressure, normal transportation of cooling water or oil that need to be carried during special processing; besides it is a double mechanism design, And it is the fourth company in the world to design a workpiece positioning system that can repeat positioning with an accuracy of 2μm, which can easily correspond to the convenient operation modes of various types of machines, improve yield and increase production capacity.

Material SUS 420, HRC 52°.

Repeatable positioning accuracy is 2 µm.

The maximum speed is 1,800 rpm.

The spring clamping force is 2,000 kg.

The air pressure boosting pulling force is 3,000 kg.

The minimum air supply pressure is 6 kg/cm².

Only the Longer Drawbar has the function of central water outlet.

Repeatable positioning accuracy is 2 µm.

The maximum speed is 1,800 rpm.

The spring clamping force is 2,000 kg.

The air pressure boosting pulling force is 3,000 kg.

The minimum air supply pressure is 6 kg/cm².

Only the Longer Drawbar has the function of central water outlet.

Fast and precise positioning: The operation time of the existing screw tightening and clamping device takes 10 seconds, and the operation time of this product is only 2 seconds, and the accuracy is 2μm.

High product compatibility: It adopts dual-mechanism clamping, which has great compatibility and wide application, and is a great tool for quick mold change.

It has the function of cooling system: there is a cooling water circuit design inside the chuck, which is mainly used for automatic chucks for high-temperature 3D metal forming machines in the cutting-edge aerospace field. There is no similar product in the market at present. .

Can cooperate with the robotic arm for automatic processing (do not need to rely on imports): Cherng Jin Technology has successfully integrated with a number of robotic arm mechanisms.

Ease of use: The positioning block can be replaced with H-type, R-type and E-type smart chucks.

Complete expansion: Optionally install related sensors (such as temperature, clamping force) to expand the functionality of the AD-148RC dual-mechanism chuck, and feedback the machine to make intelligent corrections.

High product compatibility: It adopts dual-mechanism clamping, which has great compatibility and wide application, and is a great tool for quick mold change.

It has the function of cooling system: there is a cooling water circuit design inside the chuck, which is mainly used for automatic chucks for high-temperature 3D metal forming machines in the cutting-edge aerospace field. There is no similar product in the market at present. .

Can cooperate with the robotic arm for automatic processing (do not need to rely on imports): Cherng Jin Technology has successfully integrated with a number of robotic arm mechanisms.

Ease of use: The positioning block can be replaced with H-type, R-type and E-type smart chucks.

Complete expansion: Optionally install related sensors (such as temperature, clamping force) to expand the functionality of the AD-148RC dual-mechanism chuck, and feedback the machine to make intelligent corrections.